Operating Principle

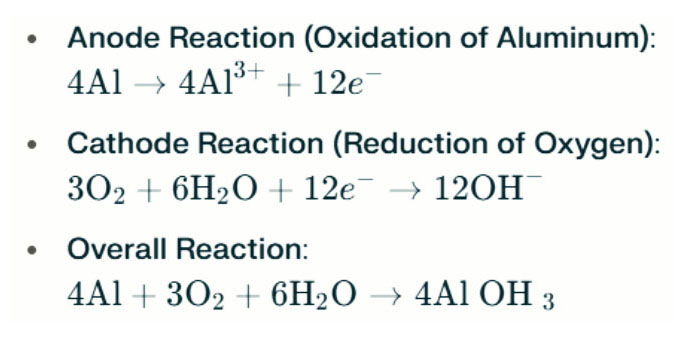

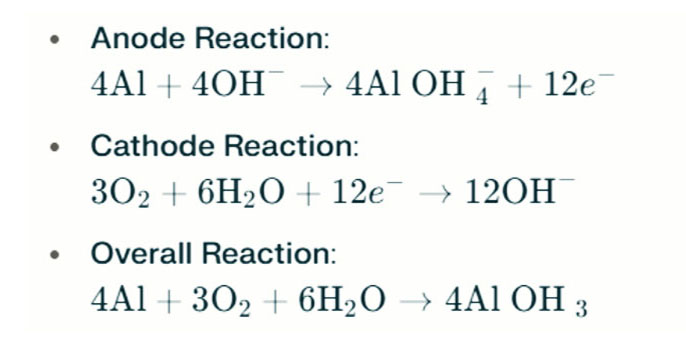

Aluminum-air battery saltwater lamps generate electricity through the electrochemical reaction between aluminum and oxygen in saltwater (the electrolyte). When the aluminum anode contacts the air cathode, it undergoes oxidation, releasing electrons and forming aluminum ions. The chemical reactions involved are as follows:

In this reaction, aluminum (Al) reacts with oxygen (O₂) and water (H₂O) to produce aluminum hydroxide (Al(OH)₃), which precipitates as a flocculent solid. Over time, these solid particles may aggregate to form larger crystalline structures. Under suitable conditions, aluminum hydroxide can further dehydrate to become aluminum oxide (Al₂O₃), resulting in a hard solid similar to concrete. This characteristic allows the resulting solid to withstand significant pressure and external forces.

Impact of Using Alkaline Electrolytes

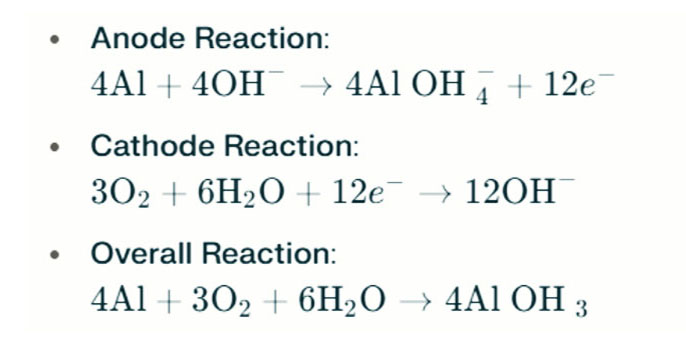

If saltwater is replaced with an alkaline electrolyte (such as sodium hydroxide, NaOH, or potassium hydroxide, KOH), the operating principles and reaction processes will differ. In alkaline environments, the reaction between aluminum and oxygen remains the primary electrochemical reaction. However, due to the alkaline environment reducing the passivation layer on aluminum, its electrochemical activity is enhanced. The reactions in an alkaline electrolyte can be represented as follows:

In this case, aluminum reacts with hydroxide ions (OH⁻) and oxygen to produce aluminum hydroxide ions.

Hydrogen Evolution Phenomenon

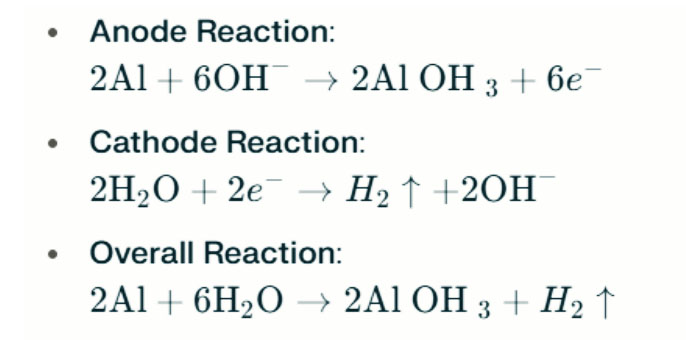

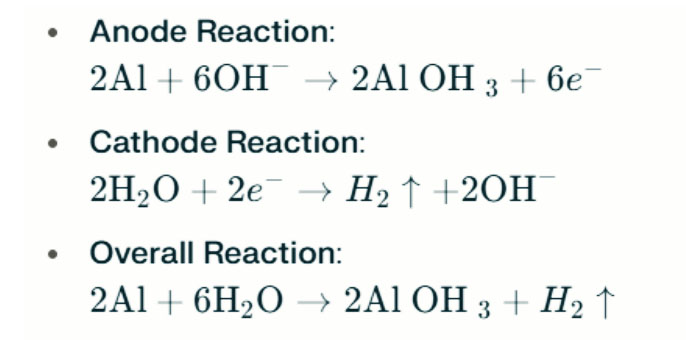

In strong alkaline environments, aluminum can undergo hydrogen evolution corrosion, releasing hydrogen gas. The chemical reactions are as follows:

Impact of Using Alkaline Electrolytes

If saltwater is replaced with an alkaline electrolyte (such as sodium hydroxide, NaOH, or potassium hydroxide, KOH), the operating principles and reaction processes will differ. In alkaline environments, the reaction between aluminum and oxygen remains the primary electrochemical reaction. However, due to the alkaline environment reducing the passivation layer on aluminum, its electrochemical activity is enhanced. The reactions in an alkaline electrolyte can be represented as follows:

These reactions illustrate the hydrogen evolution process in strong alkaline environments, which can lead to decreased battery performance.

Solid Formation and Hardening

In alkaline environments, the concentration of aluminum hydroxide ions can become high enough for them to precipitate and form solid particles. Over time, these particles may aggregate into larger crystals. The causes of solidification include:

1. Precipitation and Aggregation:

The generated aluminum hydroxide precipitates in the electrolyte and gradually forms larger particles.

2. Dehydration Conversion:

Under certain conditions, aluminum hydroxide may dehydrate and convert into harder aluminum oxide (Al₂O₃), resulting in a very hard solid.

3. Environmental Impact:

The alkaline environment may lead to denser structures in the resulting solid material, enhancing its hardness.

Summary

Thus, while replacing saltwater with an alkaline electrolyte results in similar operating principles and reaction processes, the influence of the alkaline environment on the activity of aluminum metal and hydrogen evolution corrosion can lead to differences in the final solid products and their characteristics. These changes may improve reaction efficiency but also introduce self-corrosion issues.

Usage Considerations for Saltwater Lamps

1. Chemical Reactions:

When saltwater is added, the aluminum plate reacts with oxygen in the air to generate aluminum hydroxide. This compound accumulates over time and forms solid particles that can eventually coalesce into larger masses.

1. Consumption of Aluminum Plates:

If there is a large amount of saltwater, all aluminum plates will be consumed; if there is less saltwater, primarily the lower plates will be consumed. This leads to uneven thickness among the plates.

2. Impact of Solid Particles:

As chemical reactions continue, the accumulation of internal aluminum hydroxide and formation of solid particles will increase pressure on the aluminum plates.

3. Flowability Check:

It is recommended to check the flowability of generated aluminum hydroxide daily. If flowability decreases significantly, replace it with fresh saltwater; otherwise, hardened particles may become difficult to clean.

5. Post-Usage Treatment:

If not used within three hours, immediately empty and rinse out the saltwater lamp's interior, then dry it in a ventilated area while storing it in a cool, dry place.

6. Passivation Phenomenon:

After multiple uses, residual saltwater may not be completely rinsed out, leading to passivation on the surface of the aluminum plates. When new saltwater is added, turn on the lamp first to discharge it; this will disrupt the passivation layer on the plates and restore normal operation.

7. Longevity and Eco-Friendly Features:

Saltwater lamps have a service life of at least 120 hours and can be stored for up to 20 years without requiring additional maintenance during storage. As a new type of environmentally friendly product, they are suitable for use as emergency lighting, teaching tools, or charging electronic devices in various settings such as homes, hotels, firefighting scenarios, fishing trips, hiking adventures, camping excursions, etc. Orders are welcome!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

اردو

Afrikaans

Gaeilge

नेपाली

Aymara

Беларуская мова

guarani

Krio we dɛn kɔl Krio

Runasimi

Wikang Tagalog